Air filtration

Specialized in air filtration and dust treatment, we offer a complete range of filtration products. Our team of experts will help you determine the perfect solution according to your needs.

We offer a comprehensive solution for any issues related to dust. Regardless of the particle size or density of your dust, our ready-to-use systems have been designed with high performance in mind, emphasizing automation, structural integrity, and access.

Dynagroup is equipped to work with any type of dust treatment system—from the initial design to the final delivery, installation, and implementation.

Our team stays constantly up to date with the latest standards and regulations in effect in the regions and industries we serve. These include norms concerning air quality, environmental impact, as well as safety in terms of the volatility and explosion hazard of particles (NFPA codes and standards).

- Dust collectors

- Cyclones

- Ducting, piping and capture points

- Rotating equipment

- Filters

With many years of experience in the air filtration business, we have all the solutions to suit your needs.

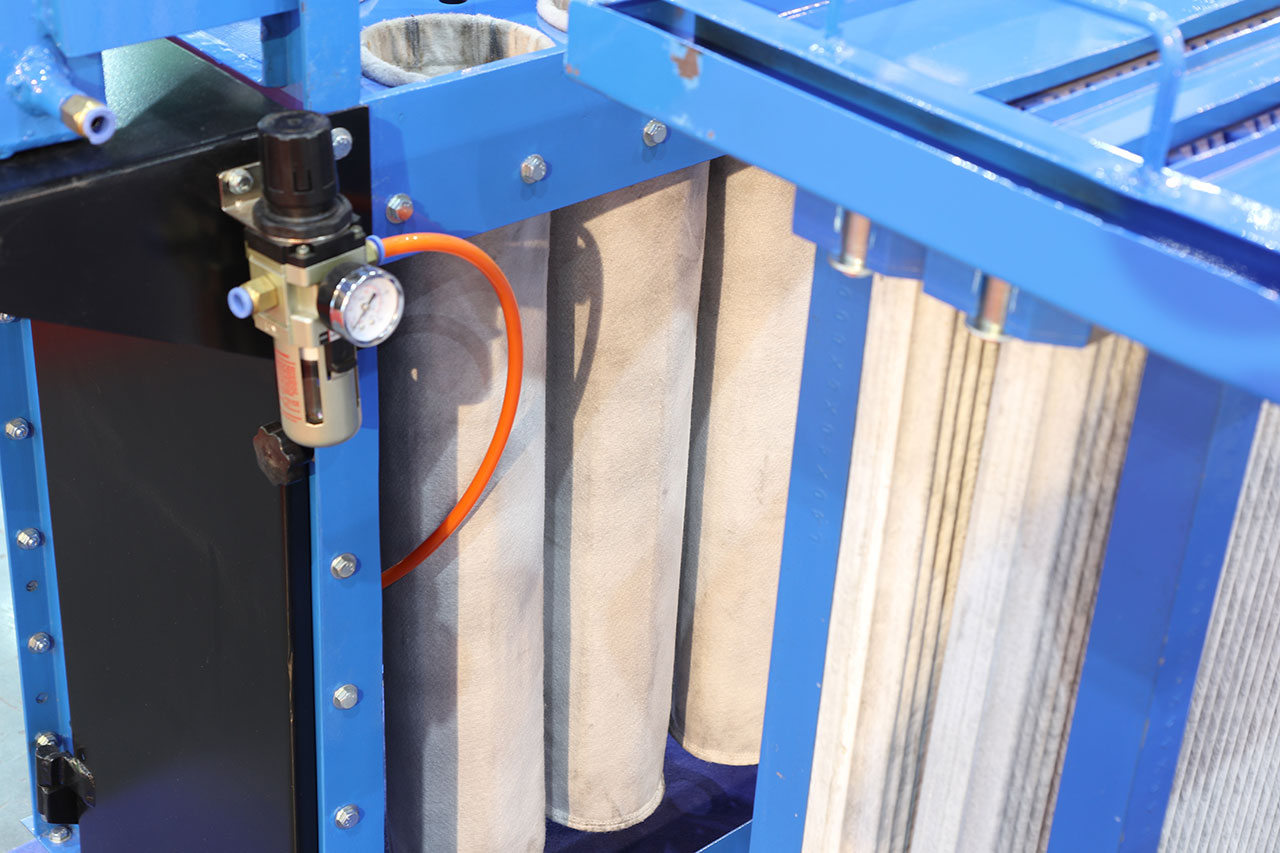

Contact usDust collectors

They can be used to collect dust for either repurposing or disposal. These dust collectors are designed in compliance with the various governmental regulations for air discharge.

Used in all industries, both primary and high technology, our dust collectors are versatile and easy to use. We ensure they are designed, manufactured, and installed correctly so that they contribute to a simple, efficient, and continuous operation. Their internal configuration is optimized for exceptional filtration, extended filter life, and minimal maintenance.

Our systems come in several configurations and materials:

- Capacity: 180 @ 850,000 m³/h (or more) (100 @ 500,000 CFM)

- Filter types: cloud bags, round bags, cartridges, specialized filters

- Media filters: polyester, aramid, PTFE, P84, etc.

- Filtration efficiency up to 99.95% (5 microns) depending on media filter and configuration

- Access to filters from the top (filtration component)

- One-piece system or modular: round, square, or rectangular

- Configuration with or without hopper

- Creation of modules according to their application

- Retro-fitting and modification of existing units to improve their capacities and efficiency

Cyclones

Cyclones, unlike dust collectors, do not use filters—the internal dynamics of the unit take care of filtration innately.

Cyclones have a lower filtration efficiency than dust collectors, which is why they are often used in tandem for the purpose of pre-separating particles. This reduces the dust load for the dust collector, extending the service life of its filters.

In some cases, one cyclone is sufficient for certain applications, but this depends entirely on the standards enforced by the region/industry.

Our team will assess your needs to find the right solution.

- Capacity: 180 @ 850,000 m³/h (or more) (100 @ 500,000 CFM)

- Complete ranges of standard models for conventional applications

- Design adapted to the industrial activity and processes, the air that needs to be filtered, and the desired efficiency

- Release cone, maintenance access, supports, related discharge equipment

- Internal lining options, adjustable entry and chimney, solutions for challenging materials

Ducting, piping and capture points

The design of the ducting network is of utmost importance when it comes to the efficiency of the overall system: from pneumatic conveyors to the largest industrial dust treatment systems.

At Dynagroup, we have the solutions and the expertise to put in place highly efficient systems. Our design considerations factor in many important parameters: diameter, speed of passage, branch connections, the radius of elbow curvature, supports, adjustment points for balancing, and so on.

Good design will help prevent duct deposits (buildup), wear and tear, premature wear, leaks, and dead zones. Moreover, a well-designed system is simple to balance and is better adapted to accommodate changes in processes over time.

We offer various types of ducting, piping, capture points, and connecting systems:

- Rolled lip ducts with variable thickness (16 ga to ½” thickness)

- Spiral ducts (14 ga to 22 ga thickness)

- Square ducts (11 ga to ⅜” thickness)

- Mounting by flange, compression collar, quick-clamp fittings, etc.

- Abrasion-resistant wear plates or “wear back” add-ons

- Hood and sensors adapted to the equipment and applications

- Access points, ductwork support systems, etc.

Rotating equipment

While filtration units are the lifeblood of every filtration system, rotating equipment is the heart. Our air filtration systems utilize the ideal amount of power to generate maximum performance and durability with minimal maintenance.

Depending on your specific applications and needs, the following equipment can be combined with our air filtration solutions:

- Ventilation systems of various types and arrangements

- Blowers of various types and arrangements

We specialize in mechanical manufacturing and integration. We work with a multitude of manufacturers of rotating equipment with no special ties to any one supplier. This gives us access to a wide range of product lines so that we can offer you the solution that best suits your needs.

Filters

We offer a wide range of filter components, and can help you select the right filters for the right applications. Regardless of the dimensions of your system, whether or not you require media filters, or whatever other specifications you might have, we’ll be able to propose the best filter to suit your equipment and needs.

We offer several types of filters, including OEM replacement filters for different units on the market:

- Round type filters: industry standard and available in a multitude of configurations

- Cloud bag filters: a new innovation to increase the filtering surface of each filter

- Cartridge filters: pleated media filter offering a superior filtration surface for each filter

- Filters of various shapes: rectangular, square, diamond, etc.

- HEPA filters: allows for recirculation in operations where filtration efficiency is essential

- Media filters: polyester, Spunbond, Aramid, PTFE membrane, nanofiber, carbon, cellulose, etc.

- Accessories: cages, collars, blanks, etc.